I heard someone once say when it comes to getting bit by a prop there are only two types of modelers… Those that have and those that will.

An online survey of powered aircraft modelers showed that roughly 60% of the respondents had been injured by a spinning propeller at least once. The stories I’ve heard over the years associated with prop injuries range from receiving minor cuts on fingers to graphic narratives, telling of extensive orthopedic surgery and months of physical therapy. There is one theme common to just about all of these stories, and that is they happened while the modeler was starting the engine.

The engine starting phase is best described as the moment the prop starts turning to when the plane is being taxied or hand launched. A high percentage of individuals who’ve been injured admit their mishap took place because they became complacent and received a sharp reminder to respect the propeller. Indecently, only a small percentage of modelers report equipment failure as the cause. That’s not to say firewalls failing; propellers coming apart or completely off, doesn’t regularly send people to the emergency room, because it does.

This article takes what those modelers have shared and turned into an outline for safely starting a gas or glow R/C airplane engine. (Electric aircraft are unique in this capacity so their safety issues will not be addressed in this article.) Multiple chapters could be written about safety near a spinning propeller and still not cover every detail. The following is just a brief outline that will hopefully make you think more about your own start up routine, there by decreasing your chance of injury.

Starting an engine safely begins well before the propeller starts turning, with inspections of the propeller, locking nut(s), spinner, motor mount and firewall. This is where a pre-flight checklist is advantageous. Full-scale pilots use a pre-flight checklist before every flight and modelers could take a lesson here to do the same as to not forget key safety checks.

Bear in mind a lot of force is being exhibited on the propeller when it is spinning. So even the slightest nick or irregularity can make it come apart even at low RPM’s. Don’t attempt to fly a prop with any issue. Even if you do manage to avoid injury, the high probability of damage to the engine and airframe just doesn’t make running a questionable propeller a worthwhile gamble.

Motor mounts and firewalls can be more difficult to check when hidden under a cowl, but these should be checked often for trouble. Engine vibrations alone often create stresses that lead to catastrophic failure. One of the more graphic stories I’ve read, complete with accompanying pictures, involved the failure of a firewall which let an engine loose to attack its owner. If I remember correctly this story included a surgery and subsequent physical therapy.

One major key to starting safety is the surrounding environment and starts with using a solid airplane restraint. Having an assistant hold the airplane does work and is better than nothing. However one injury story I read was caused by an assistant that accidentally moved the plane just as the person starting was carefully reaching near the spinning prop. If you do us an assistant be sure he/she has a clear understanding what their role is and what your intentions are before you start the engine. Trying to give commands over a noisy engine can easily result in miscommunication which often leads to an accident or a close call.

Be sure to examine the immediate area around the plane; it should be free from items that can get caught in the propeller or obstructions that could be a hindrance for safely getting the aircraft into taxi position.

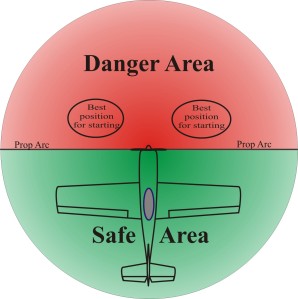

To start a plane, whether it’s by hand or with an electric starter it is best to position your body to one side of the propeller but out of the propeller arc. For those not familiar with the term “propeller arc” it is an imaginary flat plane (not airplane) that extends straight out several feet beyond tips of a spinning prop. This is the best position that will keep your body in a zone where it is less likely to be hit by anything flying off the prop or anything going forward such as the engine departing the fuselage.

A quick word about flipping a prop by hand: You should always use a starting stick (AKA a chicken stick) or wear a heavy leather glove. Just about anyone that’s started an engine by hand has a story about getting bit by a back firing engine.

It is my hope modelers know that when priming the engine the glow plug driver should be removed or ignition turned off. Stubborn engines have been known to come to life and take a modeler by surprise when they were “simply rotating a prop to prime the carb”.

Once you’ve established what your safe body position is going to be, it’s time to set up the starting environment by placing items you will need such as the transmitter, electric starter, tach, glow drive, etc, where you will have easy access of, away from the spinning prop. Make sure there is no loose clothing or items hanging from you, like a transmitter neck strap, which can contact the prop.

When it’s time to get the engine running, get your mind on the task, block out any diversions, forget for a moment that joke you just heard. If someone is helping you, make eye contact with them to be sure their attention is with you and they are ready to assist. Make a quick check of the area to make sure no one is in the immediate vicinity of the prop arc or the danger zone. Throttle position on the transmitter should be just high enough to get the engine started. If you do need to use a high throttle to start, idle down ASAP.

Once the engine is running, if you had one hand on the fuselage, like most modelers do, use a slow deliberate, wide motion away from the prop as your arm and hand transition through the prop arc. Also be conscious of cords to starters and glow drivers. Adjusting the needle valve, removing the glow plug driver and running the engine above idle should ALWAYS be done from behind the prop.

Of course this requires moving around the plane to be behind the prop arc. Doing so with your transmitter, eliminates any need to reach through the prop arc. Also from this position you immensely reduced the chances of injury from a malfunction. It is important to note when moving around the plane, be sure to use extreme caution to avoid tripping on anything or bumping the airplane. Several people have been injured in those circumstances.

This diagram shows which areas around a plane are considered safe and which are dangerous.

Before running the engine up to a high RMP, check to make sure the prop arc and area forward for several feet in any direction is clear of bystanders. As rare as prop breaking may be, a few people can tell you how amazingly deep a piece can be imbedded into flesh. Also it’s necessary to point out that a transmitter should not be attached to you at this point, by way of a neck strap or a transmitter tray. A modeler should ‘strap in’ only after they are satisfied the engine is running the way they want it and the airplane is prepared for flight and ready to taxi. I’ve heard stories of modelers that bent over to do something with the airplane. With the TX clipped to his neck strap he ended up loping off a section of antenna with the prop.

Once the needle valve has been adjusted and the run up check is complete, position the throttle on idle to remove the airplane from the restraint. This is the time where an assistant is beneficial as it’s nice to have somebody hold the transmitter while the other moves the plane. Whether you carry your plane or pull it by the tail to get it into taxi position, always be thinking about the buzz saw located on the front of the airplane.

Most transmitters these days have a throttle to lock, (a button that locks the throttle into its current position regardless of where the stick is moved after). If you need to learn how to use it, do so and get in the habit of using it every time your plane is being handled by a person or when your attention needs to away from an idling plane for even just a second.

The ultimate key is to develop a safe routine for starting. One school of thought is that any time a routine is interrupted even slightly, the probability of something bad happening goes way up. I firmly agree with the belief that anytime you get interrupted during the starting procedure, go back to the beginning and start over.

With the plane ready to taxi that concludes the start up phase and begins the flying phase, which is a completely different set of safety issues. Without a doubt, a modeler somewhere could read any aspect of this article and say, “I did that and still got hurt”. None of this information will prevent injury. It hopefully will greatly reduce the chance. One piece of advice that I found very constructive is to “watch out for your buddy”. Not in the sense that he’s dangerous. Although don’t rely on other people for your safety. The idea of watching your buddy is if you see a fellow modeler about to do something that causes concern or if something doesn’t look right, warn them.

Keep in mind watching out for your buddy is a two way street. Check your ego at the front gate and allow them to point out concerns for you without ill feelings. Sometimes another set of eyes just might be at a better angle to see something potentiality dangerous. Keep in mind too, when a fellow modeler is starting and adjusting an engine, let them concentrate on the task at hand and don’t become the reason for them having an accident.

To conclude this article I’ll do so with a message that was repeated over and over by modelers carrying battle scars… THINK and FOCUS! Don’t allow yourself to get complacent around a spinning propeller!